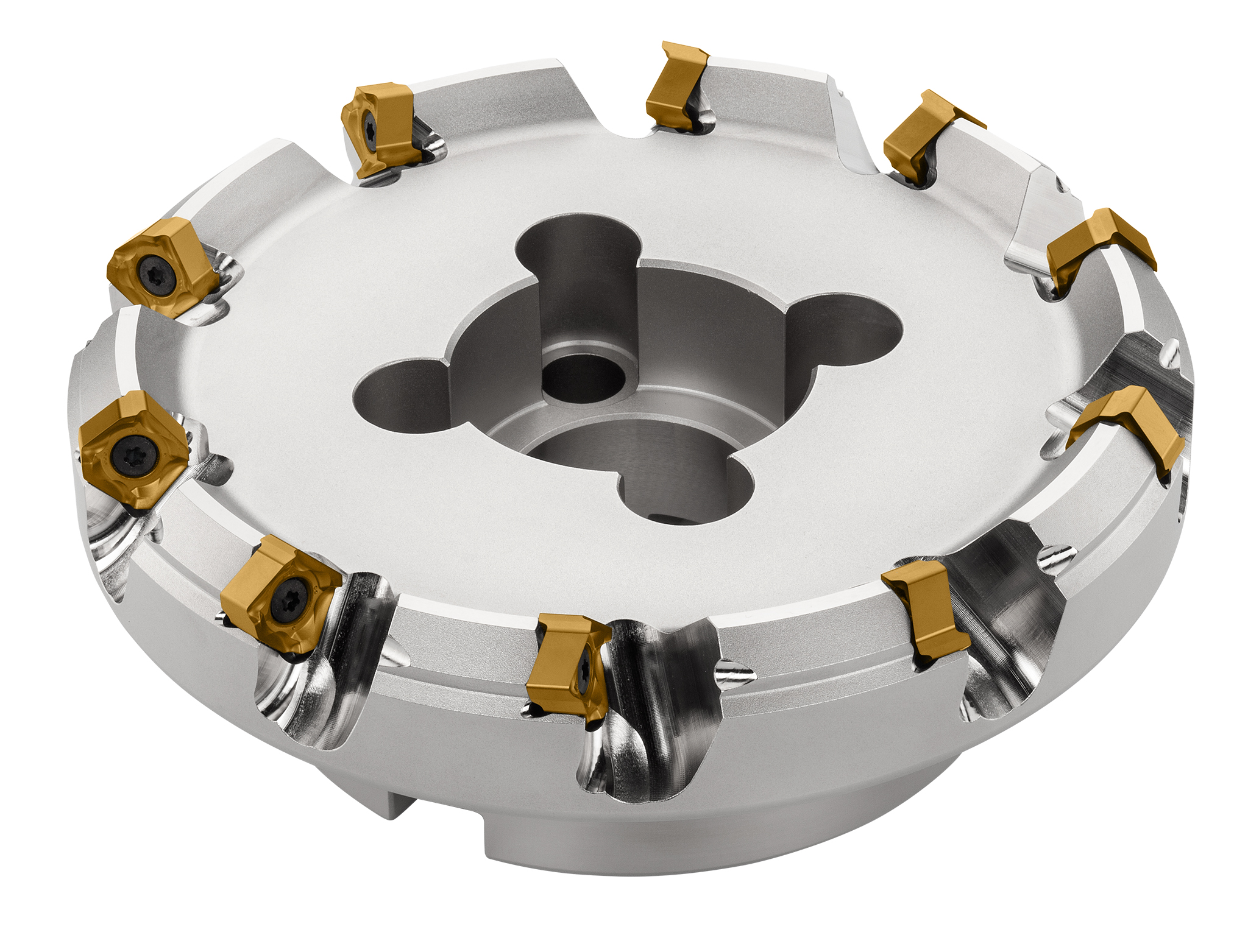

WSX445

Low Cutting Resistance Face Mill

- Economical, 8 cutting edges

- Low cutting forces for small machines

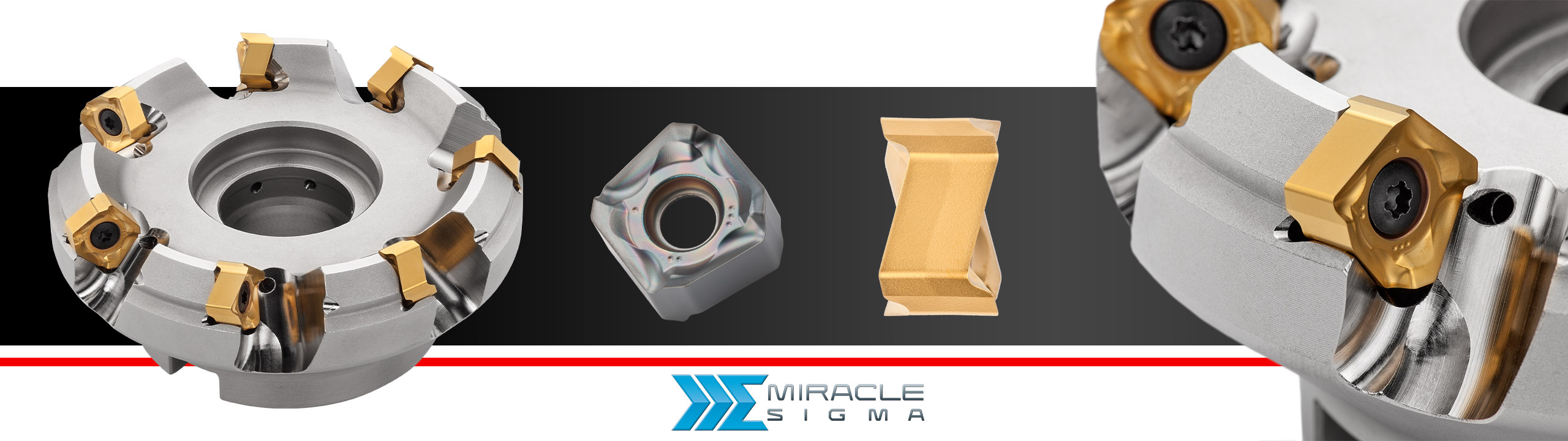

- Wide range of MIRACLE SIGMA inserts for high performance

New WSX series - low cutting resistance face mill

The WSX445 face mill is a next generation face milling cutter designed to elevate the performance level when machining steels, cast iron and stainless steels, as well as nickel based and titanium alloys.

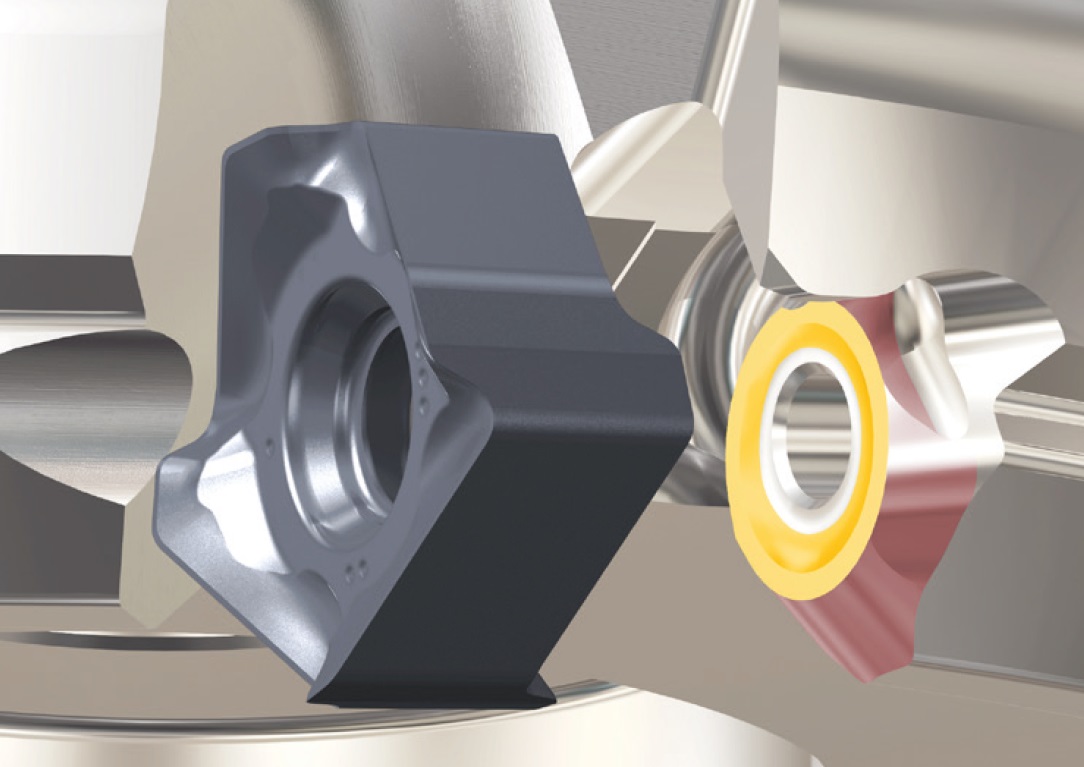

Embracing the latest MIRACLE SIGMA technology WSX445 uses inserts with advanced cutting materials, new geometries and coatings. Compared to conventional milling cutters, WSX445 uses unique double sided inserts instead of the standard single sided types. This means there are 8 fully functional cutting edges on each insert and are available in various chipbreaker geometries. This intelligent synergy ensures economically efficient production processes and added value for users without any loss in surface finish quality whilst also maintaining the required smooth cutting action for overall high Performance.

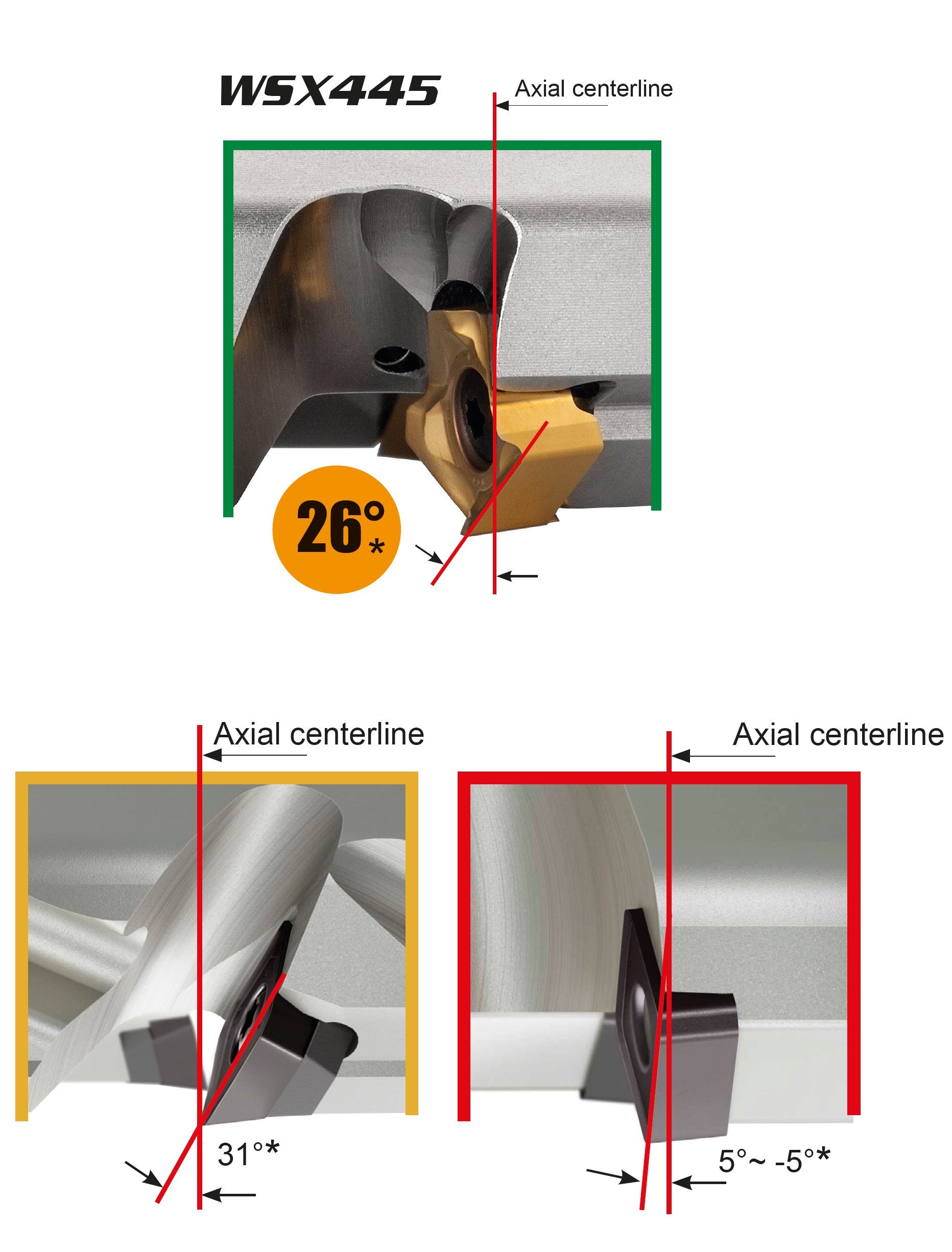

Innovative Insert Geometry

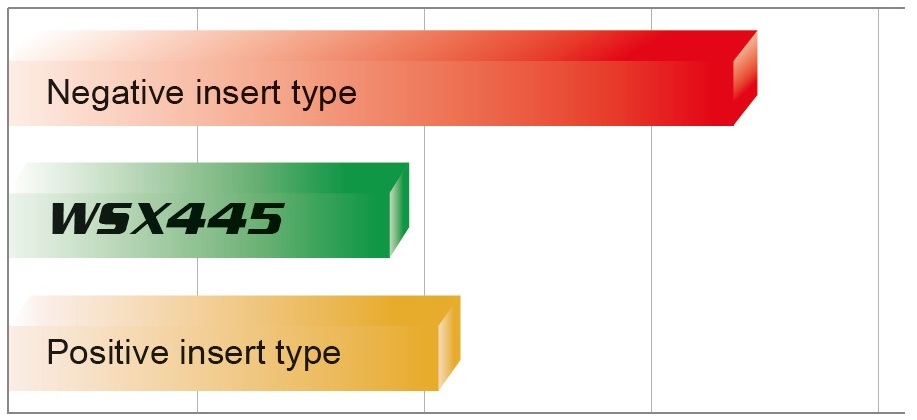

The positive geometry of the Double Z inserts for the new WSX series takes face milling to a new level of usability. The low cutting resistance the geometry produces makes it ideal for all types of machines, from low power through to heavy duty types. This level of cutting resistance is only usually associated with conventional single sided positive inserts and allows end users to increase machine utilization. The new moulded SNMU and SNGU G class type inserts used on the WSX cutter have all the attributes of a single sided positive geometry insert but importantly, also have the advantage of being double sided with a cost saving, 8 cutting edges.

The cutting edge of the Double Z geometry inserts are set at a 26º positive axial rake angle when clamped in situ. This provides the perfect solution that includes a strong but sharp cutting edge whilst allowing the inserts to be double sided. Furthermore, a large 5mm max depth of cut is possible.

Cutting resistance (N)

Reliability

A predictable and safe performance is demanded by today’s customers and the WSX series meets these criteria with strong insert clamping and an Anti –Fly mechanism.

Through coolant holes are also provided as standard in cutters under Ø160 for efficient chip removal and cooling to further enhance process reliability.

Wide Application Area

The WSX series comes complete with a comprehensive range of insert grades to cover a huge range of material applications, from steels and stainless steels through to cast iron, heat resistant materials and hardened steels. The latest TOUGH-Σ technology is used in the new MP range of insert coatings to provide enhanced heat and wear resistance and provide a low coefficient of friction, lending further help towards the ultimate aim of complete process reliability.

The inserts are equipped with a series of chip breakers specifically designed to cover a varied range of applications. L breaker has a positive land for lighter cutting and the lowest cutting resistance, M breaker is for general cutting and R breaker has enhanced edge strength for unstable cutting. The WSX series also includes a wiper insert geometry for smooth surface finishes.